- Best quality

- Quick assembly

- Longevity

Solex|SolarBloC®

Solar

thermal

systems

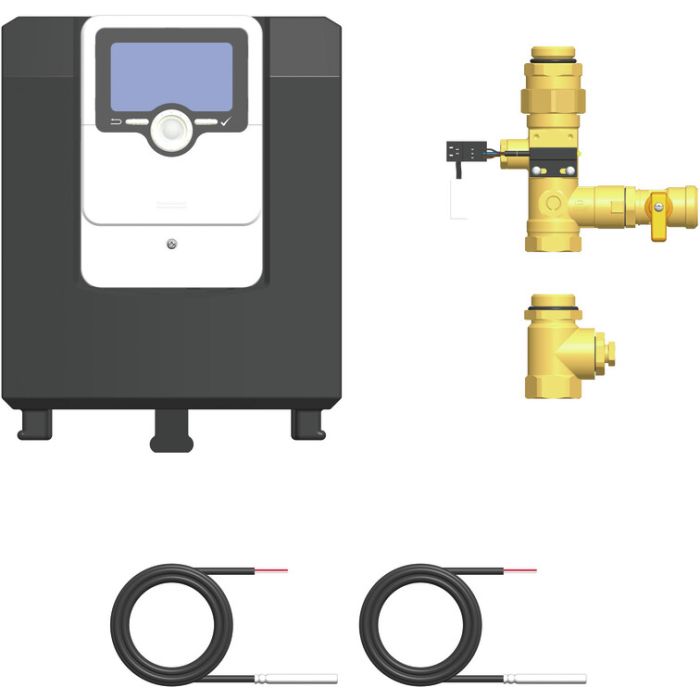

Ergänzungsset zur Wärmemengenbilanzierung

Sicherheitshinweise Die Installation und Inbetriebnahme sowie der Anschluss der elektrischen Komponenten setzen Fachkenntnisse voraus, die einem anerkannten Berufsabschluss als Anlagenmechaniker/in für Sanitär-, Heizungs- und Klimatechnik bzw. einem Beruf mit vergleichbarem Kenntnisstand entsprechen [Fachmann]. Bei der Installation und Inbetriebnahme muss Folgendes beachtet werden: - Einschlägige regionale und überregionale Vorschriften - Unfallverhütungsvorschriften der Berufsgenossenschaft - Anweisungen und Sicherheitshinweise dieser Anleitung

WARNUNG Verbrennungs- und Verbrühungsgefahr! Die Armaturen und die Solarflüssigkeit können Temperaturen von über 100 °C aufweisen. Die Solarflüssigkeit kann als Dampf austreten und zu Verbrühungen führen. - Führen Sie Wartungsarbeiten nur bei Kollektortemperaturen unter 50 °C aus. - Warten Sie, bis sich die Solarflüssigkeit auf max. 50 °C abgekühlt hat. ,WARNUNG Gefahr für Leib und Leben durch Stromschlag! - Vor elektrischen Arbeiten den Netzstecker ziehen! - Stecken Sie den Netzstecker erst nach Abschluss aller Installations-arbeiten, Spülen und Befüllen in eine Steckdose. So verhindern Sie ein unbeabsichtigtes Anlaufen der Motoren. - Machen Sie bei allen Arbeiten die Station allpolig stromlos. - Der elektrotechnische Anschluss muss durch eine Elektro-Fachkraft erfolgen. - Die Station(en) sind gemäß den geltenden Gesetzen an eine Erdung an zu schließen.

VORSICHT Personen- und Sachschaden durch Überdruck! Durch Schließen beider Kugelhähne im Primärkreis trennen Sie die Sicherheitsgruppe vom Wärmetauscher. Durch das Aufheizen des Speichers können hohe Drücke entstehen, die zu Sach- und Personenschaden führen können! - Schließen Sie die Kugelhähne nur im Service-Fall.

HINWEIS Sachschaden durch Mineralöle! Mineralölprodukte beschädigen die EPDM-Dichtungselemente nachhaltig, wodurch die Dichteigenschaften verloren gehen. Für Schäden, die durch derartig beschädigte Dichtungen entstehen, übernehmen wir weder eine Haftung noch leisten wir Garantieersatz. - Vermeiden Sie unbedingt, dass EPDM mit mineralölhaltigen Substanzen in Kontakt kommt. - Verwenden Sie ein mineralölfreies Schmiermittel auf Silikon- oder Polyalkylenbasis, wie z. B. Unisilikon L250L und Syntheso Glep 1 der Firma Klüber oder Silikonspray.